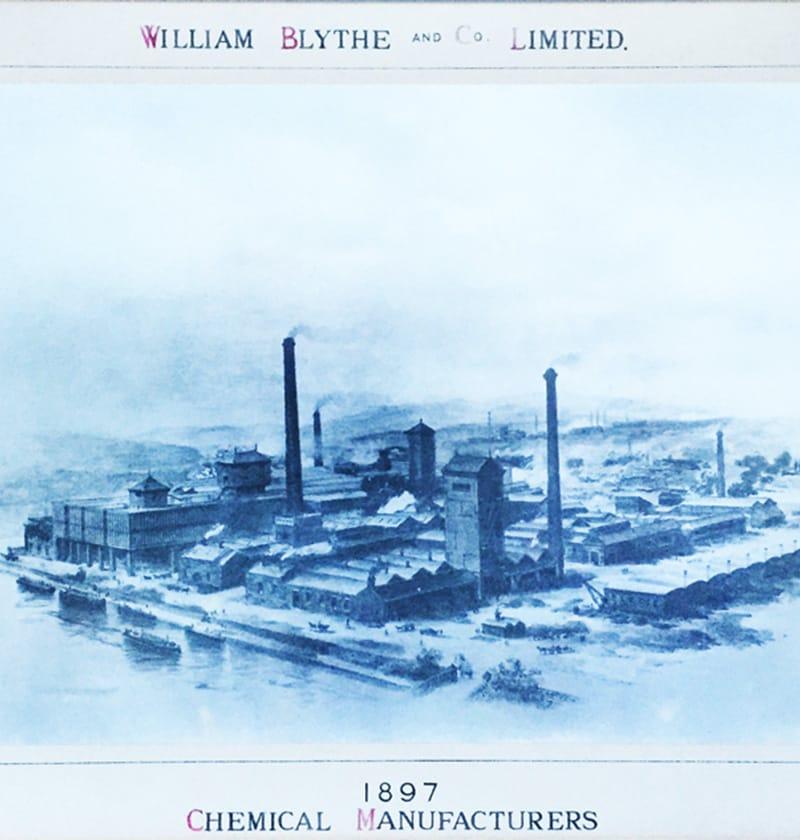

William Blythe Limited was founded in Accrington, Lancashire, by Scottish chemist William Blythe after graduating from the University of Manchester

The company’s first patent was granted for the manufacture of sulfuric acid.

William Blythe & Co. Ltd was established with William Blythe’s sons, William Steward Blythe and Frederick Charles Blythe, as Directors.

William Blythe & Co. became a global supplier of inorganic chemicals with sales to the Americas, Europe, Asia and Africa. It also helped to support the war effort during the First World War.

A turning point in the mindset of William Blythe as chemical engineering talent is brought in to the company to develop new processes rather than using external contracting firms. This led to the development of in-house expertise handling strong acids, bases and oxidants through the use of plastics, corrosion resistant metals such as titanium and tantalum, and GRP tanks.

Acquired by Hickson & Welch (H&W) to safeguard the supply of arsenic salts from William Blythe, key constituents of H&W’s inorganic wood preservative business. The handling of hazardous materials such as arsenic has led to William Blythe holding a wide regulatory permit and unique licenses for handling and processing hazardous chemistries.

Commenced development of the Flamtard products in association with Alcan. This year also saw the construction of a facility to produce sodium metaperiodate, another core chemical in William Blythe’s current product portfolio.

Further investment in the Quality Control and R&D Laboratories to meet the requirements of highly specified products and to support new product development.

The launch of the graphene oxide as a commercial product along with the webshop, GOgraphene, a leading storefront for academics and industry to purchase small quantities of graphene oxide.

Successful installation of the hydrothermal plant, a new capability which enables the production of functional nanoparticles.

The graphene oxide process is successfully scaled to a 50-tonne capacity of high purity dispersion.

Installation of new laboratories at our Accrington site. This 250 m2 facility includes a polymer application suite, flame retardant testing, small scale electrochemical device testing and process scale-up.

Contact us today.

We use necessary cookies to make our site work. We'd also like to set analytics cookies that help us make improvements by measuring how you use the site. These will be set only if you accept.

For more detailed information about the cookies we use, see our Cookies page.

Necessary cookies enable core functionality such as security, network management, and accessibility. You may disable these by changing your browser settings, but this may affect how the website functions.

We'd like to set Google Analytics cookies to help us improve our website by collecting and reporting information on how you use it. The cookies collect information in a way that does not directly identify anyone. For more information on how these cookies work please see our 'Cookies page'.