We have developed a vast amount of experience and knowledge in the production of inorganic materials. Underpinning everything we do is operation at the highest standards of quality control. This runs through both product, quality performance and service that we offer our customers.

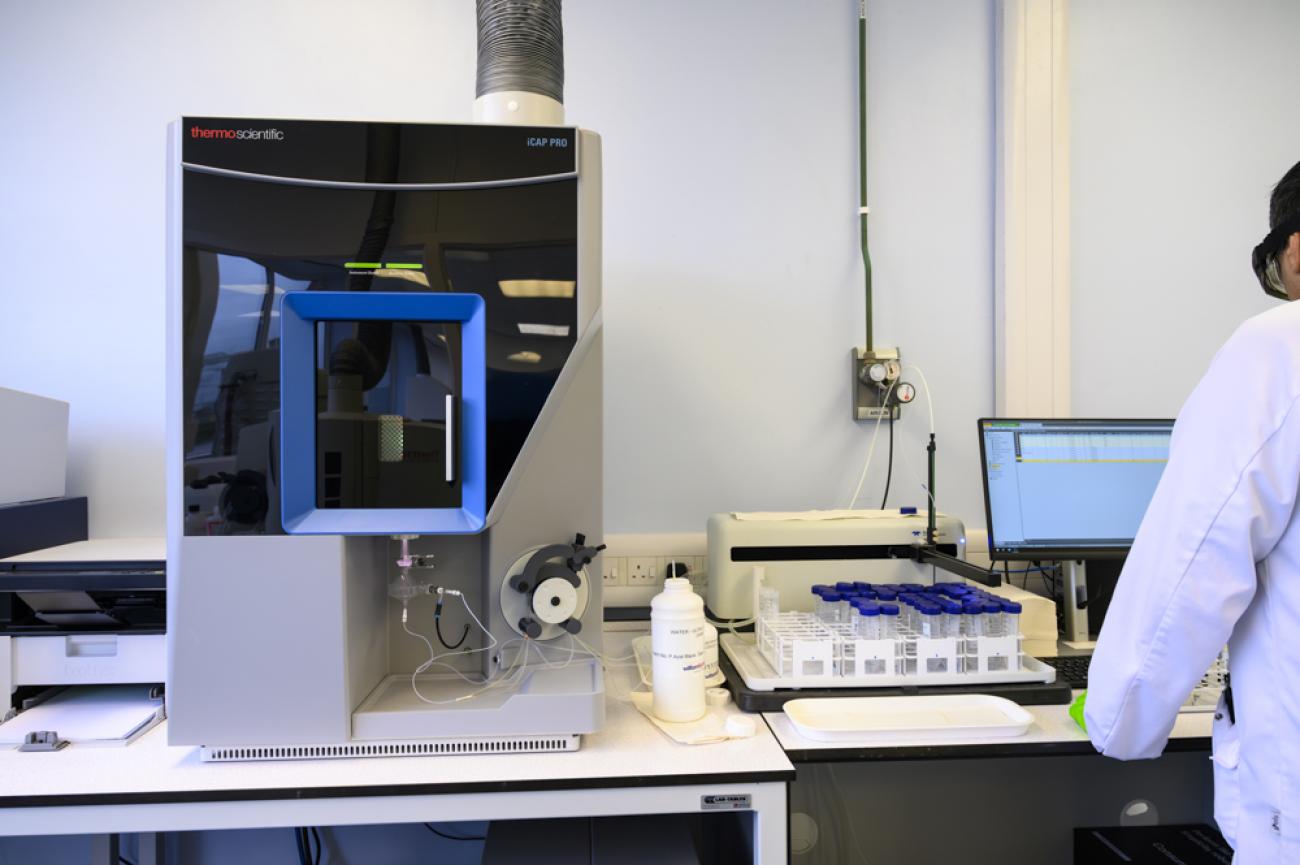

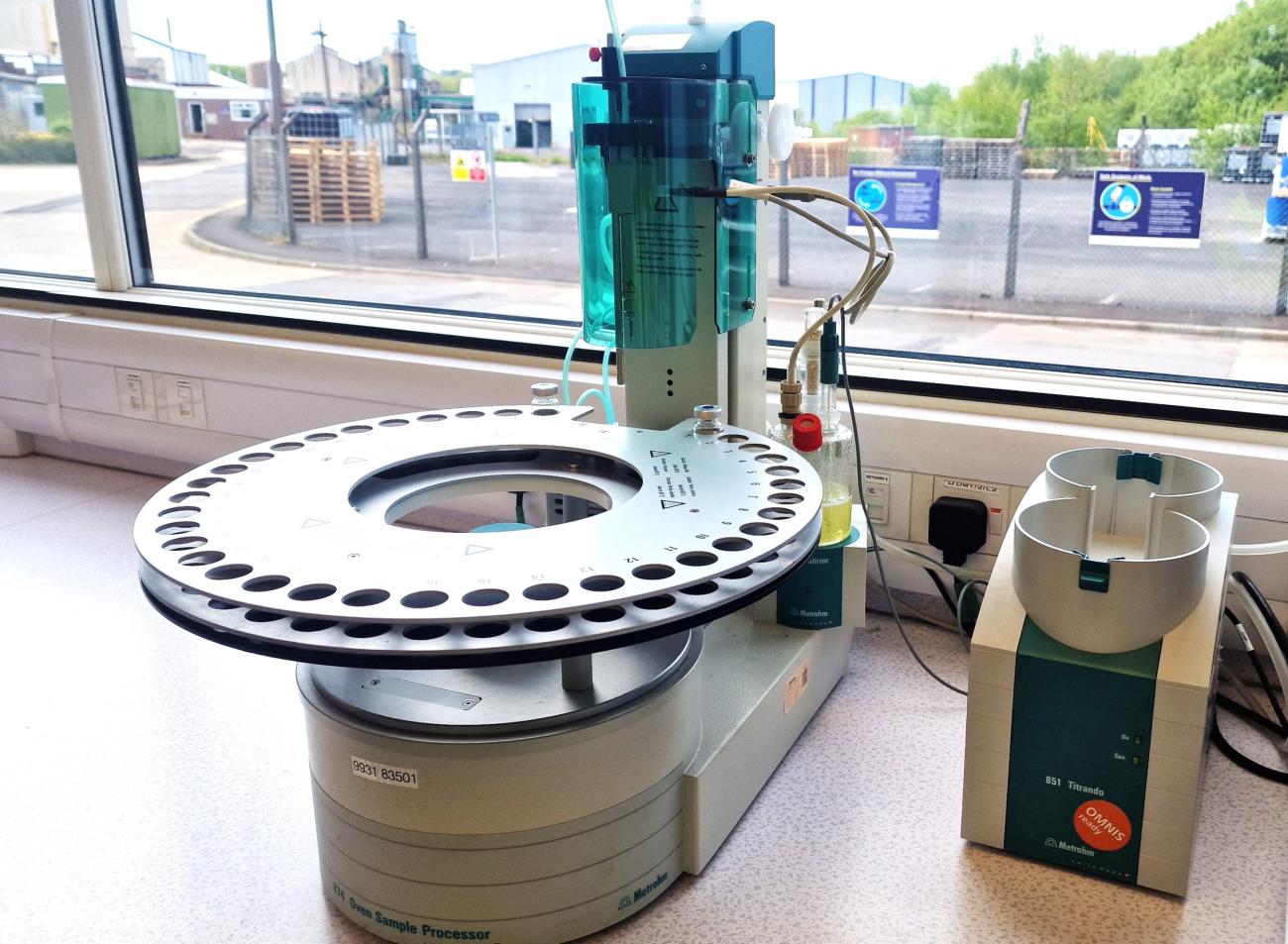

Quality Control

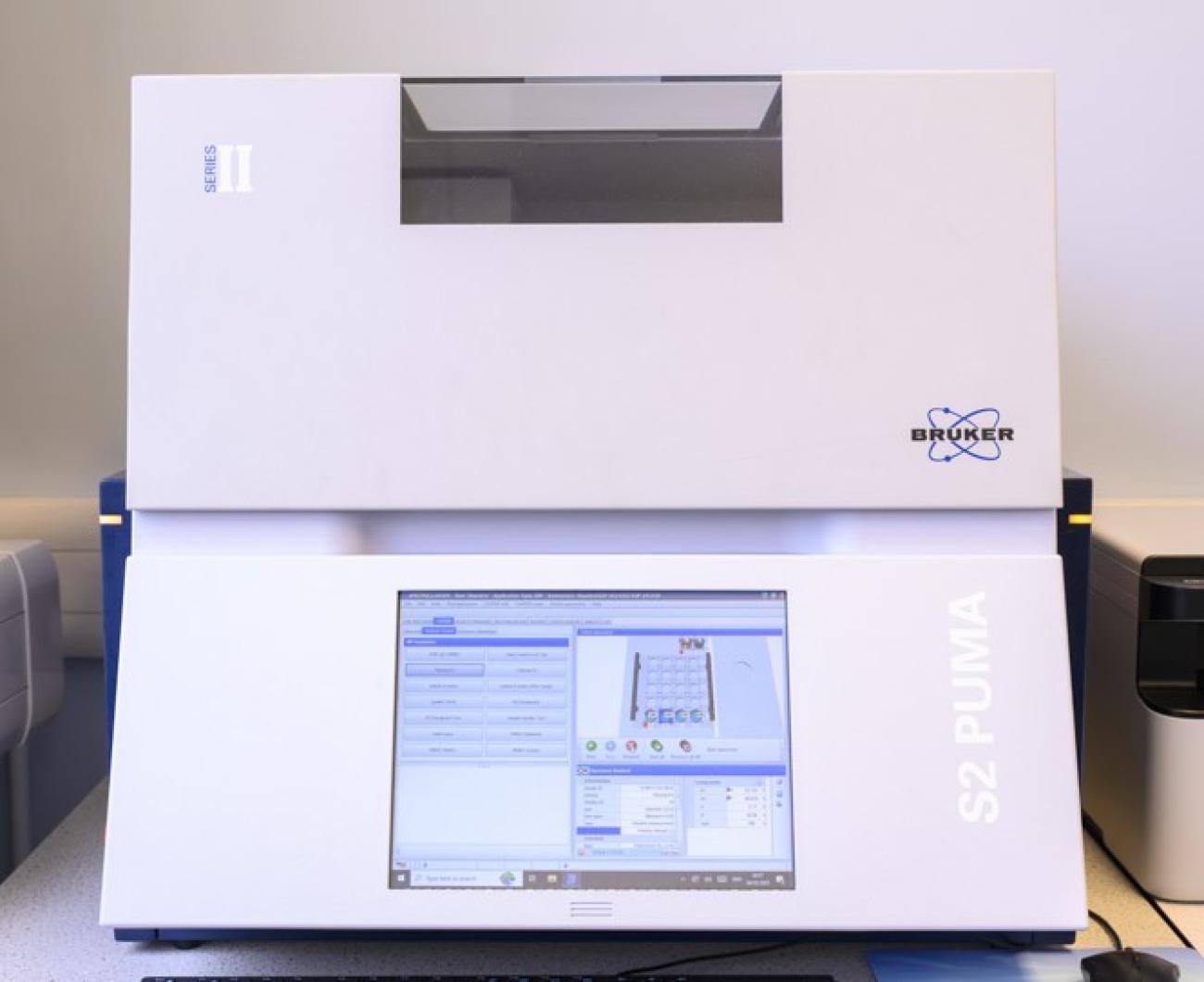

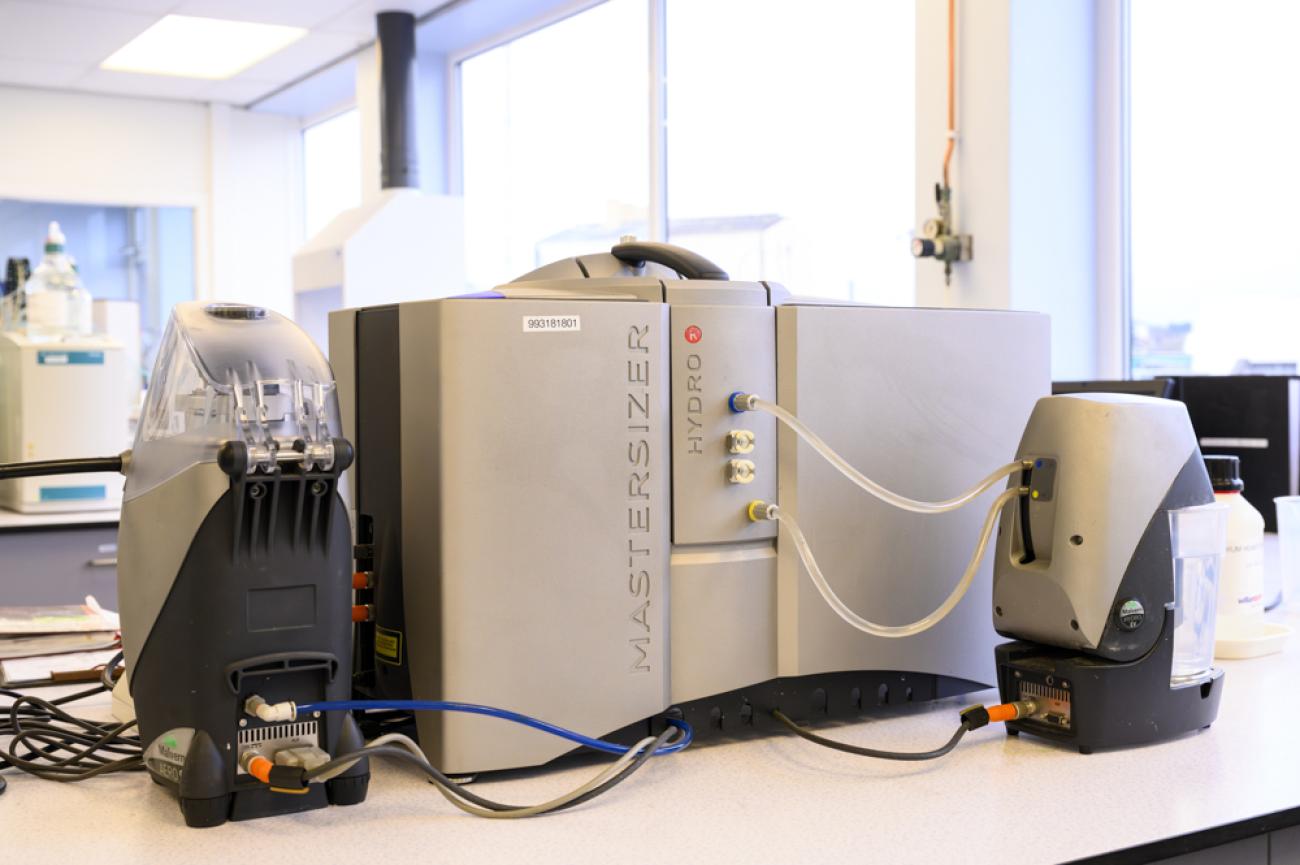

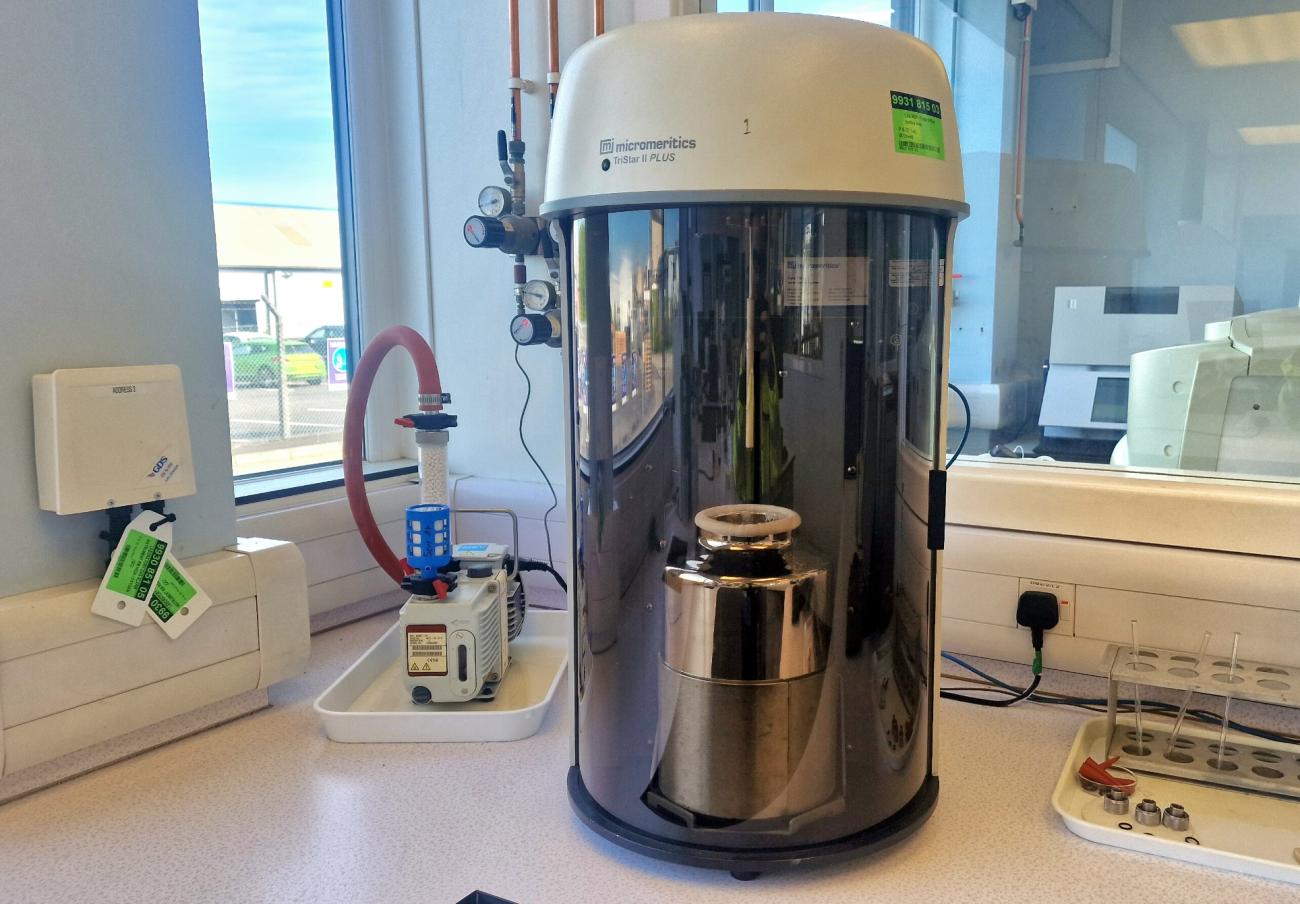

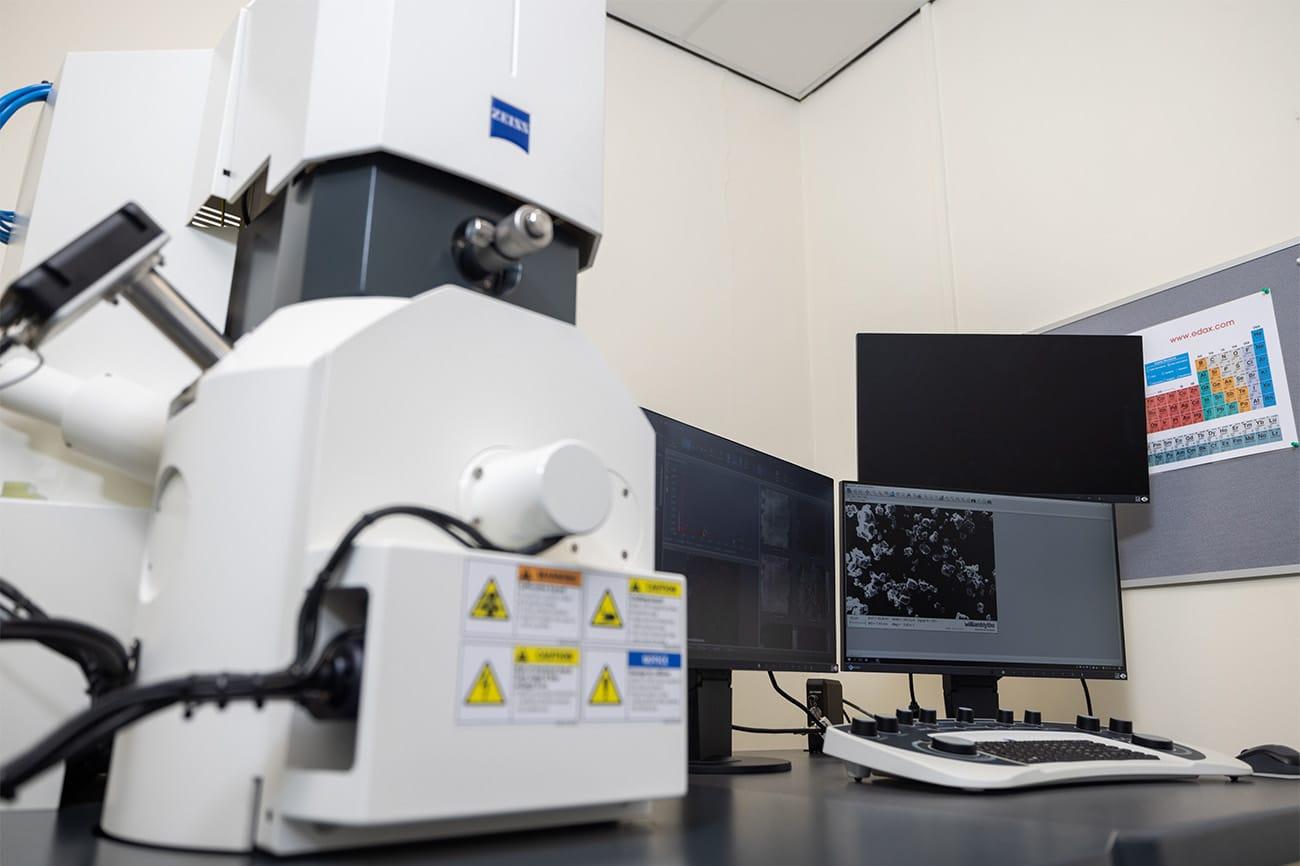

We aim to ensure the highest levels of quality in everything we do. Our Quality Management System is ISO 9001 accredited and our team strives to exceed customer expectations in quality control and customer service. Our quality control laboratory is equipped with advanced analytical techniques, enabling us to characterise the chemical and physical properties of every batch manufactured at William Blythe.

Manufacturing Capabilities

Our core capability is the manufacture of rigorously defined, high purity functional inorganic chemicals. This is achieved through a range of chemical processing routes including bi-tri metallic precipitation, redox chemistry and hydrothermal synthesis. Once the target chemical is manufactured, we have a toolkit of purification techniques that we can employ to produce high purities to specification. We also utilise post processing techniques such as blending, granulation and masterbatch production.