Sulfur and Mercury Removal

William Blythe offers fixed-bed absorbent products for sulfur and mercury removal in natural gas processing plants under the DURAGUARDTM product family.

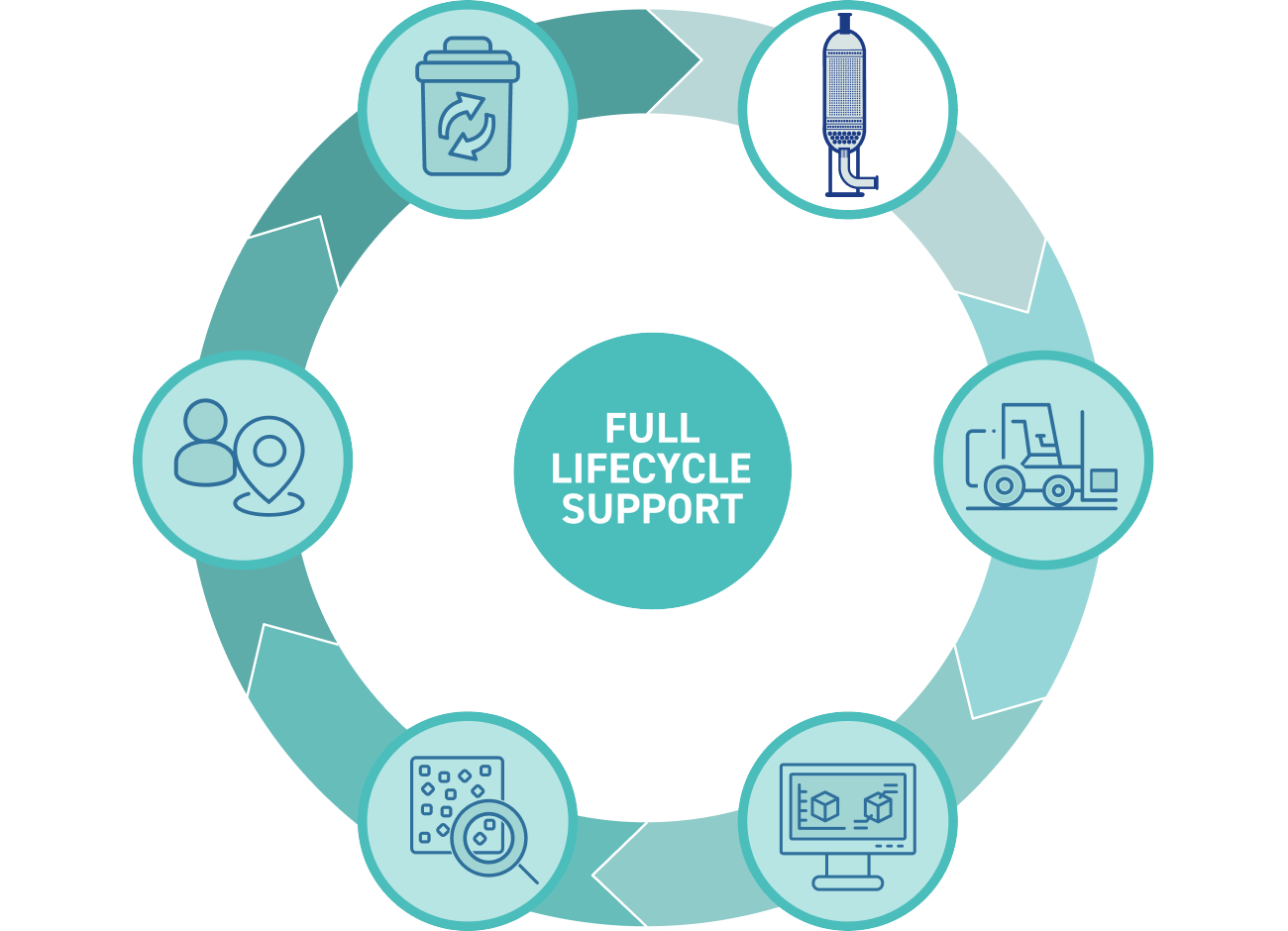

DURAGUARD™ absorbents have high capacity, long-life and are a cost-effective solution for gas & liquid gas streams. All DURAGUARD™ products come with a full lifecycle support package from a team with 50+ years’ experience in gas processing.

DURAGUARD™ product benefits:

Low capital cost

High capacities for mercury & sulfur

Stable pressure drop through life

Spent material can be reprocessed

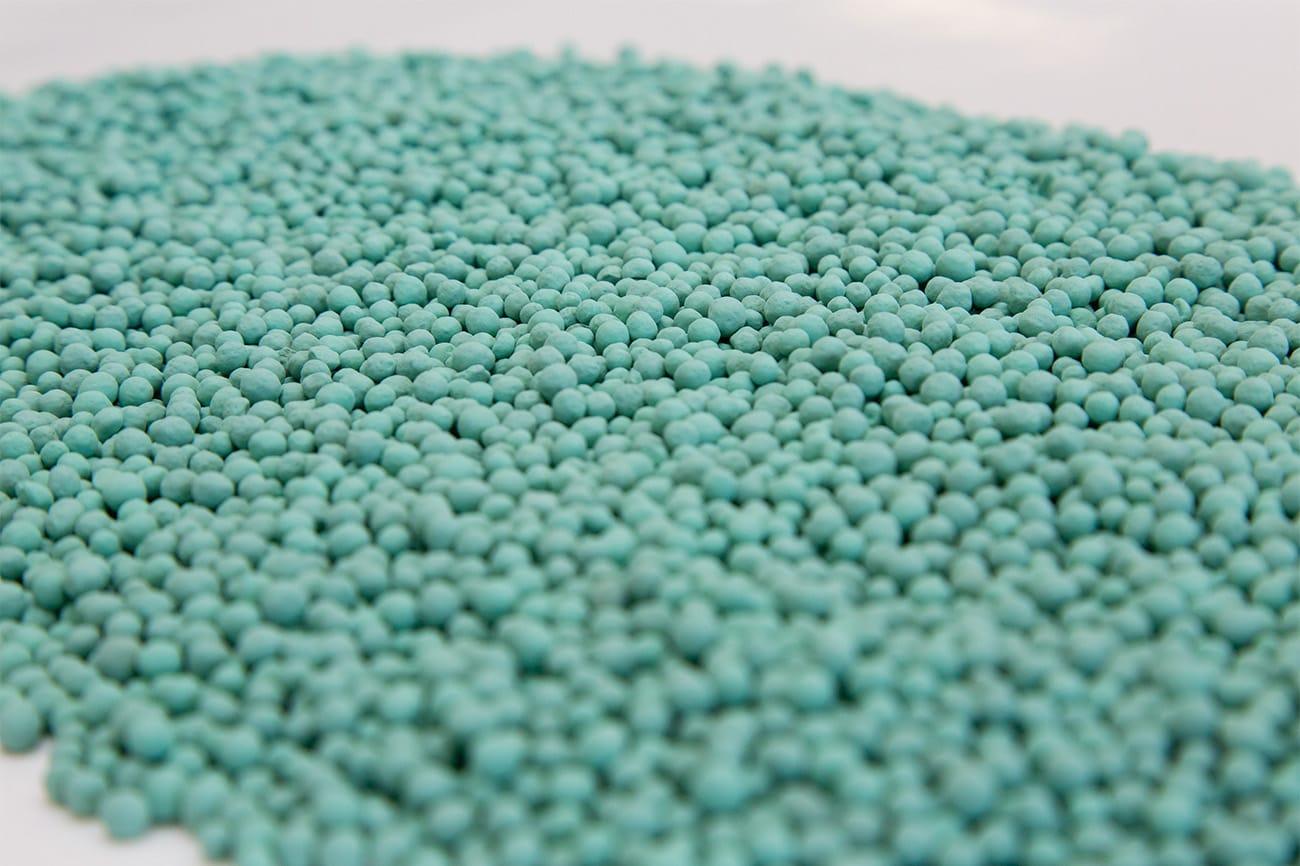

DURAGUARD S100

DURAGUARD S100 is a fixed bed gas absorbent for hydrogen sulfide removal in gas processing plants, optimised for high capacity.

DURAGUARD S200

DURAGUARD S200 is a fixed bed gas absorbent for hydrogen sulfide removal that has been designed to maximise both capacity and cost benefits of DURAGUARD products.

DURAGUARD M100

DURAGUARD M100 is a fixed bed gas absorbent engineered with very high capacity for mercury removal in gas processing plants.