Bi-Tri Metallic Precipitation

Controlled bi-tri metallic precipitation is the precipitation of metal salt solutions to produce a wide range of metal oxides, hydroxides, iodides and carbonates. We are not limited to our core chemistries and can work with most metals in the periodic table. We have extensive knowledge in controlling the physical properties of our products which directly link to their performance as absorbents, catalysts and flame retardants.

-

Surface Area

-

Morphology

-

Density

-

Particle Size

-

Crystallinity

-

Porosity

Redox

We have decades of experience in handling strong oxidizing and reducing agents to control the oxidation levels of our products, whilst ensuring physical properties and colour remain in the desired range for our customers. For example, we take iodine from 1- (potassium iodide) up to 7+ (sodium periodate) and have developed a safe manufacturing route to graphene oxide.

-

Control of Surface Oxidation

-

Experience in Handling Hazardous Chemistries

-

Metal Dissolution Technology

-

Particle Size

-

Colour

Hydrothermal

Hydrothermal synthesis is the manufacture of products in an aqueous medium at high temperature and pressure. This enables the production of mixed metal salt nanoparticles at precise dopant levels. Hydrothermal reactors are available at every scale from the laboratory through to a multi tonne manufacturing facility.

-

Nanoparticle Manufacturing

-

Stable Dispersions

-

Controlled Dopant Levels

-

No Noxious Chemicals

-

Tight Control of Particle Size

Purification

1. High Purity Materials & Electronics Grade Material

We supply a number of our products into the electronic industry where ppb or ppt levels of trace impurities are required. Propietry purification techniques have been developed to achieve these low levels and advanced ICP equipment is used to characterize these.

2. Ion Exchange & Electrodialysis

Two techniques employed to achieve low purity levels in William Blythe products are ion exchange and electrodialysis.

3. Statistical Quality Control

We have extensive experience of Statistical Quality Control (SQC) and deliver our products where required not to specification but within control. This gives our customers complete assurance that the product they receive will perform exactly the same every time.

4. Membrane Filtration

As we develop new materials with ever decreasing particle sizes, traditional dead end filtration technologies such as belt filters, nutsches and filter presses do not give the required level of filtration performance due to blinding of the filter medium. To address this issue we have developed membrane filtration where we are able to produce high purity nano-particles with very low levels of trace impurities.

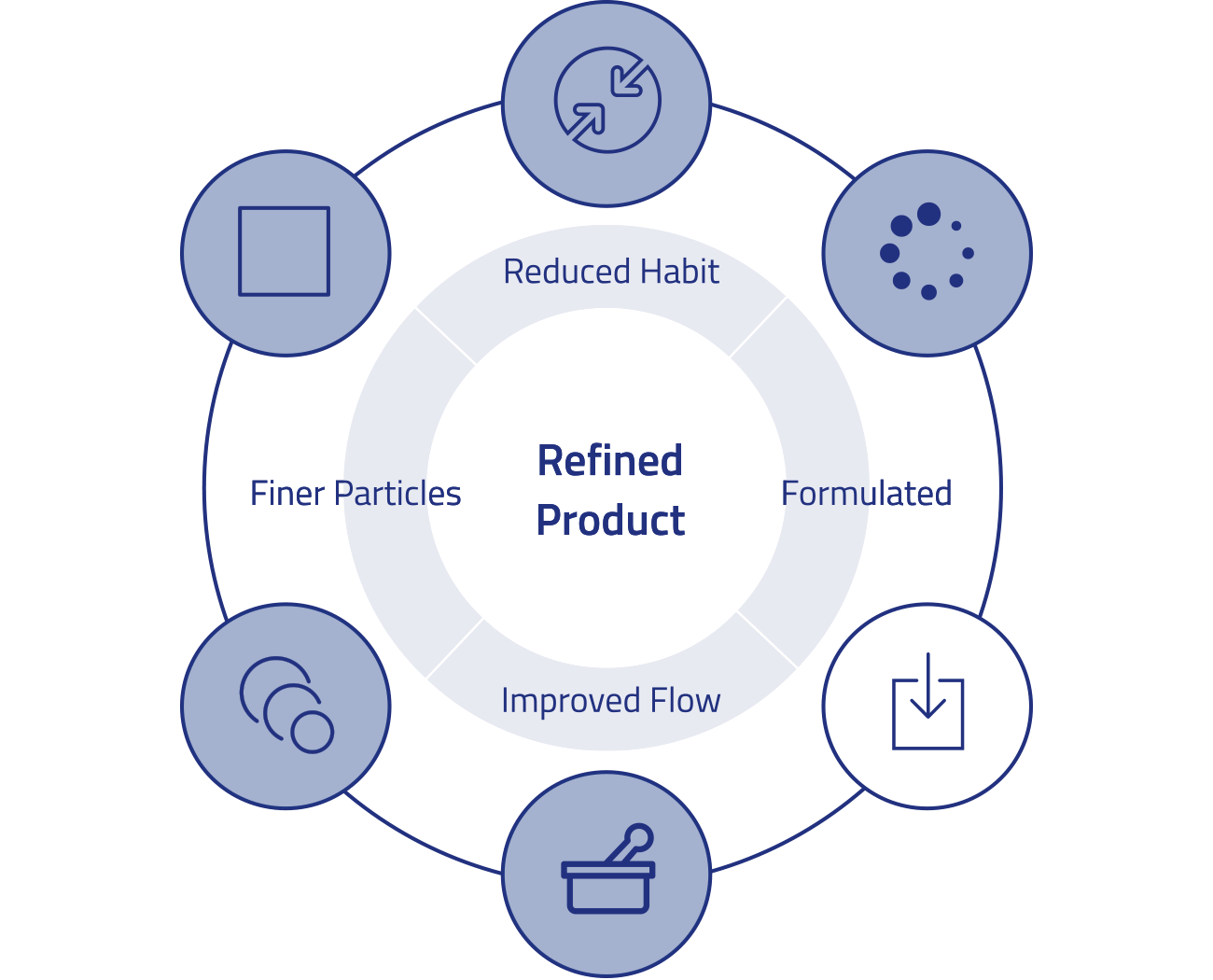

Post Synthesis Enhancement

1. Roller Compaction

Where we cannot produce the required product characteristics by first intent during the chemical process, we have developed a number of product refinement techniques to improve the performance of our products. Roller compaction can be used to densify a product.

2. Granulation

Granulation can be used to form a durable formed article from a powdered product so that it can be used directly in application

3. Extrusion

A technique commonly employed to form active ingredients into a polymer matrix to create a “masterbatch”. We can use external partners to create masterbatch products for our catalysts, flame retardants and graphene oxide products.

4. Milling

We employ milling techniques to reduce the particle size of our products down to the customers specification. This can include ball milling, bead milling and jet milling.

5. Blending

Blending can be used to provide a multifunctional product, reduce oxidation or create a free flowing powder. We use external partners to create custom blends to customer specifications.

6. Surface Treatment

Surface treatment can be applied to powders to compatibilise with the matrix that they’re being applied to, reduce hazards and promote free flowing properties.

Learn how our knowledge could benefit your organization

Contact us today.