William Blythe is delighted to announce the launch of their new absorbent product, DURAGUARDTM, designed to remove sulfur from hydrocarbon streams.

After many years manufacturing the inorganic chemical powder ingredients used for absorbent and catalyst manufacture, the move to produce our own granulated finished absorbent product was a natural evolution. The outcome, combining innovation in chemistry with our expertise in manufacturing technology, is a high capacity absorbent offering unrivalled durability and performance to natural gas processing operators.

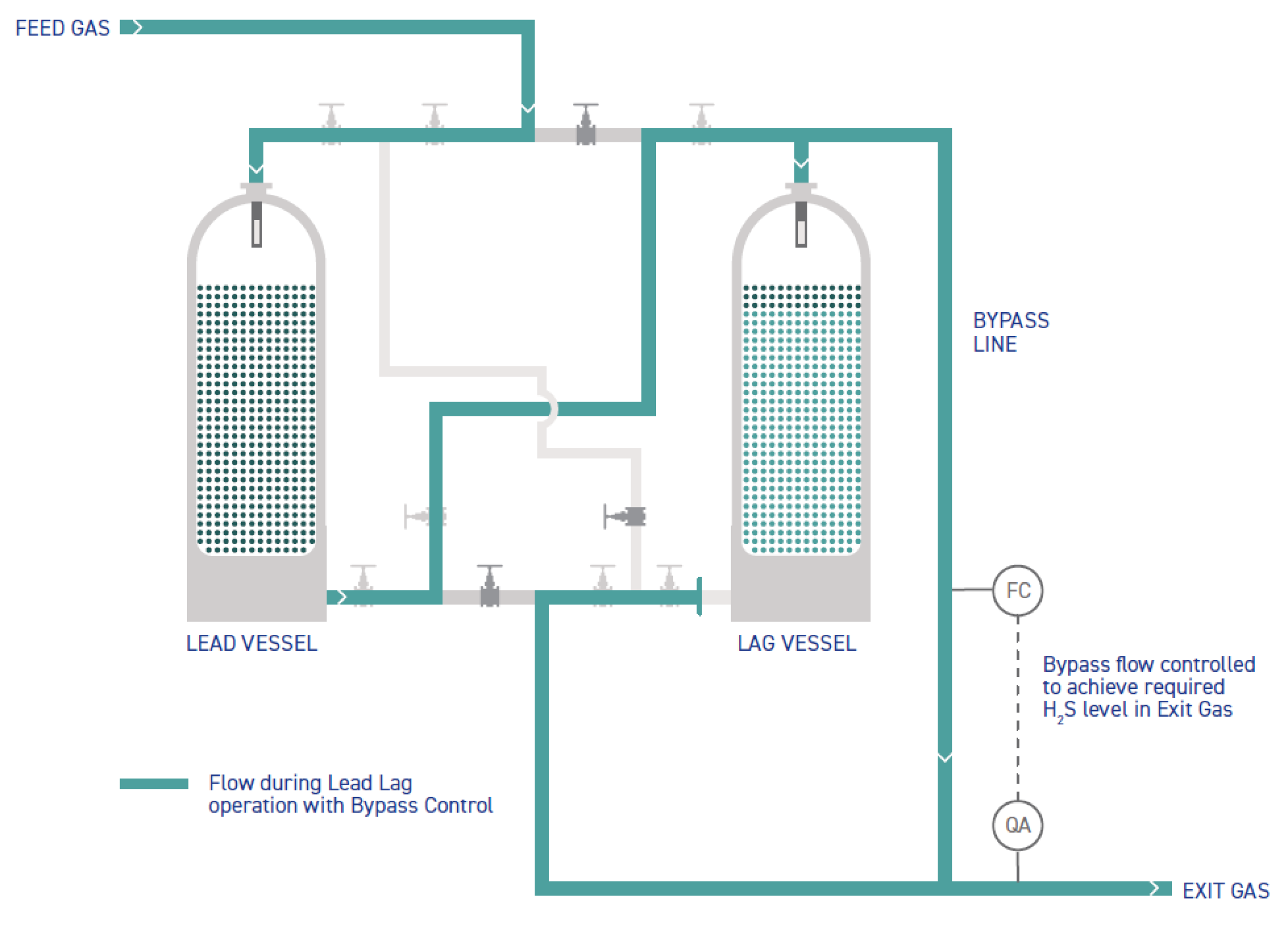

The DURAGUARD S100 product variant can be used by operators for sulfur removal from hydrocarbon gas and liquid streams. The DURAGUARD S100 absorbent is engineered to have enhanced porosity, resulting in a very high capacity for H2S. Operating Benefits include impurity removal to very low levels. Product life depends on the amount of H2S that passes through the bed, allowing for variations in the gas flow and impurity level. The sharp absorption profile means that single bed operation is possible. However, a lead-lag configuration offers the flexibility to change-out spent absorbent while the plant is on-line allowing continuous, uninterrupted operation.

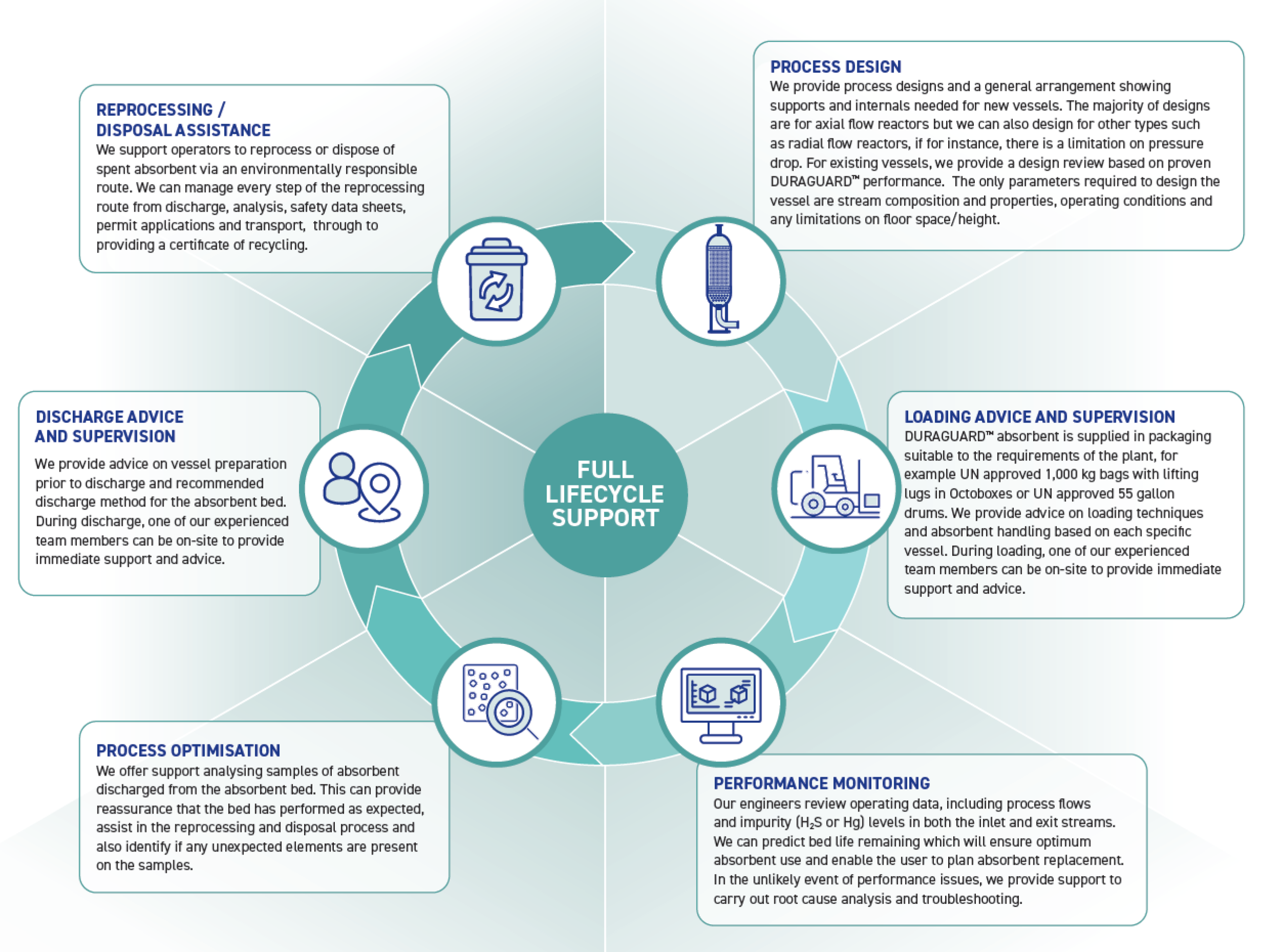

We offer customers a turnkey, full solution approach comprising: technical support for the full life-cycle of the absorbent, providing designs for new beds, advice and supervision on loading and un-loading of absorbent, process optimisation during operation and the re-processing of spent absorbent. Reprocessing of spent DURAGUARD absorbent via environmentally friendly and sustainable routes can be managed by William Blythe, ensuring minimum environmental impact from the process.

To find out more about our DURAGUARD products, click here.