We have world class research facilities and a team of highly skilled scientists ready to provide inorganic material solutions for the challenges of tomorrow.

We have a strong track record of taking new innovations from lab scale to industrial manufacturing.

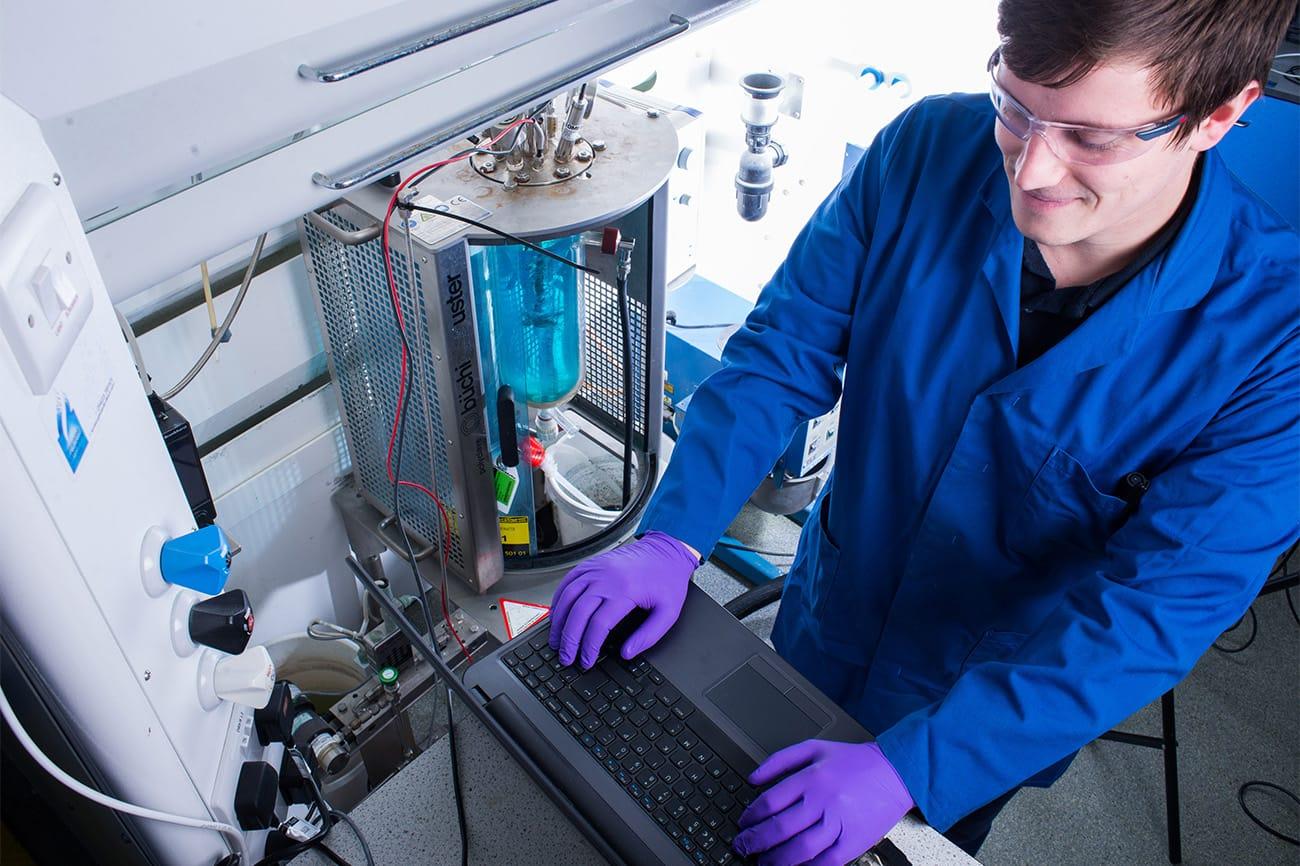

Chemical Development

Our R&D team have extensive knowledge of bi-metallic and tri-metallic precipitation reactions, continuous flow reactors, hydrothermal synthesis, redox chemistry, electrochemistry, calcination and purification. We’ve worked with blue-chips, start-ups and academia in developing scalable manufacturing routes to new inorganic materials.

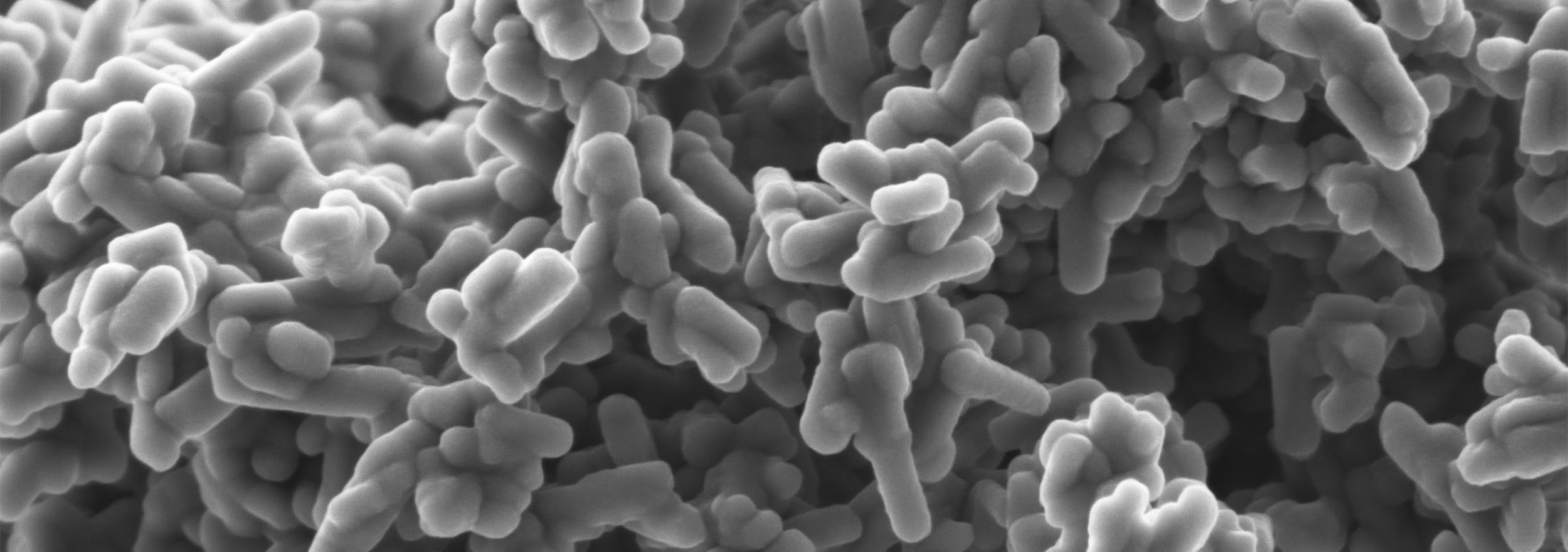

Characterisation

Control of the physical and chemical properties of inorganic chemicals is our core capability. We have a suite of materials characterisation techniques to ensure product quality throughout scale up including SEM, XRD, XRF, ICP-OES, TGA/DSC, surface area, particle size and metal assay.

Technologies For Tomorrow

We have developed functional materials that enable many new advanced technologies.

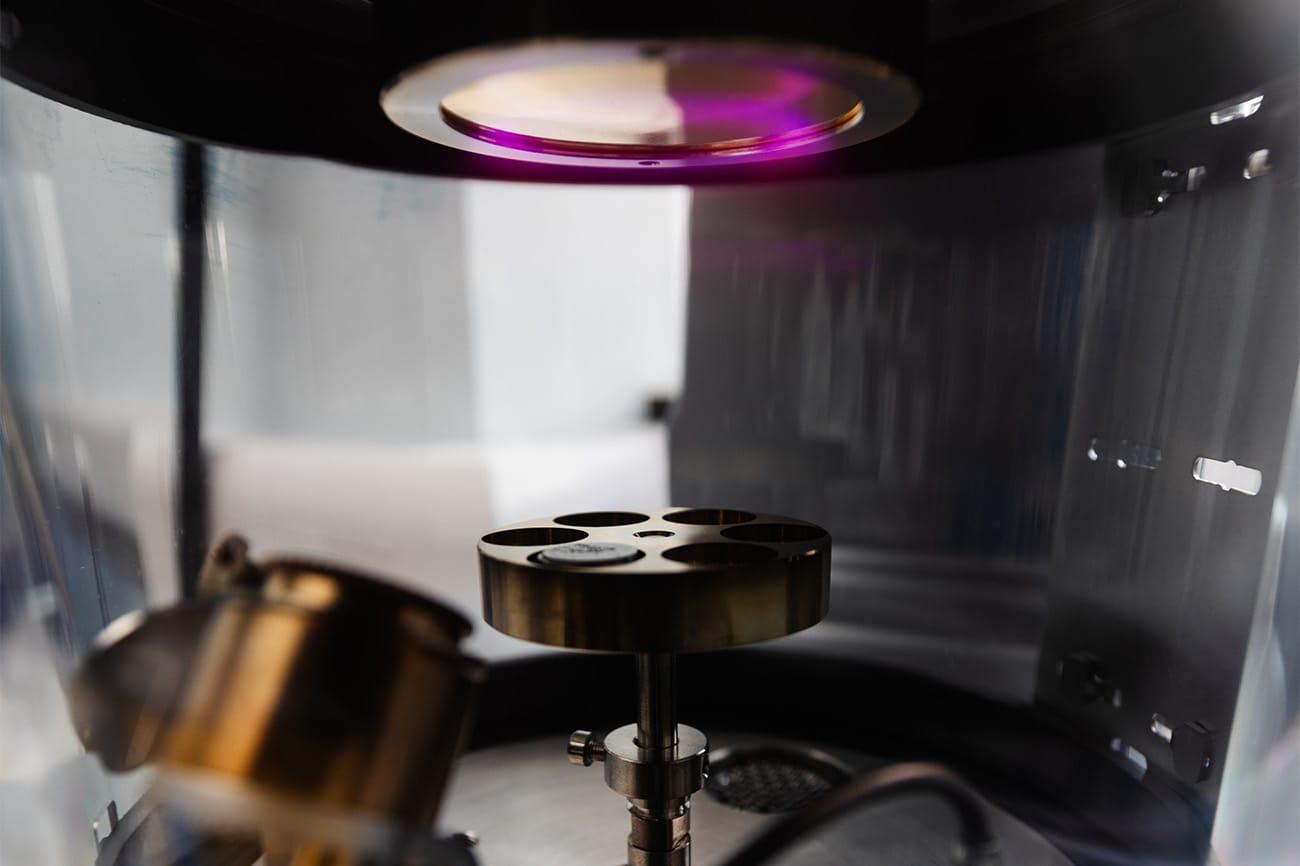

Process Scale up

When working on innovation projects for customers, we can take new process routes from gram to kilo to hundreds of kilogram quantities in our R&D laboratories. In 2022 we installed a new scale-up facility designed to take new processes to industrially relevant reactors, allowing us to supply new materials at 100’s kg quantities for pilot scale processes.

Pilot Manufacturing

It is crucial to have flexible pilot scale manufacturing assets to transfer lab processes and demonstrate scalability. Our R&D team work hand in hand with our chemical engineers and analytical chemists to ensure that new processes are effectively and safely transferred to pilot scale manufacturing.

Application Testing

We have capabilities for lab scale testing across a range of industries including polymer processing, fire testing, gas absorbent capacity and batteries.